Indice de production: la perte d'huile est inférieure ou égale à 2%, l'humidité est inférieure à 0,2%, les acides gras libres FFA sont inférieurs ou égaux à 5,5%

Avantage: assemblage modulaire économe en énergie, transport facile et déplacement de la production

Le recyclage des sous-produits d'usine, l'auto-approvisionnement en électricité, le degré élevé d'automatisation et la réduction des coûts de main-d'œuvre.

| 01 |

1. Section de réception des grappes de fruits de palme Rampe de chargement: déchargement des fruits de la paume, nettoyage, plates-formes de stockage, décharges hydrauliques segmentées. |

|

| 02 |

2. Section de stérilisation Les grappes de fruits frais de palme sont acheminées vers le réservoir de stérilisation à l'aide d'un transporteur à raclettes et d'une cage à fruits pour effectuer une stérilisation à haute température (145 ℃, 90 à 120 minutes). fournir les conditions de base pour le traitement ultérieur. Modèle de réservoir de stérilisation 1.Horizontal 2. Vertical Les clients peuvent choisir le type de stérilisation en fonction de leur situation réelle. |

|

| 03 |

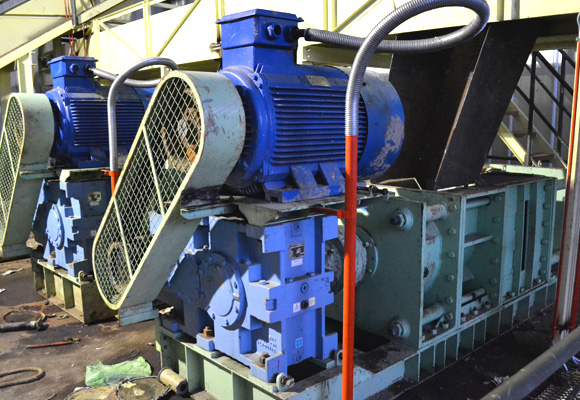

3. Section de battage Les grappes de fruits de palme frais sont stérilisées et transportées vers le tambour de battage, qui peut séparer les particules de fruits des grappes en les faisant pivoter et les battre. Ont principalement les caractéristiques suivantes: 1. conception coaxiale; Adoptez des roulements à alignement automatique à double rangée pour assurer la coaxialité, une forte stabilité, un faible taux d'échec et un entretien facile. 2. adopter un démarrage progressif; La broche a un couple important au démarrage, ce qui causera de graves dommages à l'équipement et à l'équipement de transmission. Nous utilisons le coupleur hydraulique pour démarrer progressivement côté moteur et utilisons le réducteur de vitesse à courroie de type V. Assurer la stabilité de la phase de démarrage. |

|

| 04 |

4.Ripe Fruit pressing section The main equipment of the pressing station is digester and press machine: 1. The palm digester machine is mainly used for breaking the fruit and heating the fruit before the whole fruit enters the presser; The main models are: 2000L, 3000L, 3500L, 4500L. 2. Double screw press is double screw extrusion of the broken fruit, and equipped with a hydraulic system as an aid to ensure that the residual oil in the cake is reduced and the integrity of the palm kernel. The main models are: 5t (FFB) / h, 10t (FFB) / h, 15t (FFB) / h, 20t (FFB) / h |

|

| 05 |

5.Crude oil filtration section 1. Initial filtration of the hard and fibre impurities in the pressed crude palm oil; 2. Double filter, upper filter 20 mesh , lower filter 40 mesh 3. The filtered crude oil enters the crude oil tank, and the hard and impurities are recovered and repressed. |

|

| 06 |

6.Clarification station The main role of the Clarification oil section is to remove stearine and water from the oil by means of settling, centrifugation, vacuum drying and the like at an appropriate temperature. The main equipment is as follows: 1. palm crude oil shaker;(removal of impurities and hard ) 2. Vertical Clarification oil tank;(separation of dirty oil and clean oil) 3. Disc centrifuges;(separation of water in clean oil) 4. Vacuum drying system;(removal of residual moisture in clear oil) 5. Sand cyclone ;(remove the sand in the oil) 6. Three-phase decanter centrifuge(separation of oil,water,slag from dirty oil) 7. Crude Palm oil storage tanks.(palm oil storage) |

|

| 07 |

7.The storage of crude palm oil and transport 1.Palm oil crude oil heating storage 2.Crude palm oil transport |

|

| 08 |

8.Empty fruit bunches processing section: The residual oil is recycled, and the shredded empty fruit string is used as a fertilizer or fuel for the boiler. |

|

| 09 |

9 fibre separation section Through floating dry processing the fruit core and fibres separated. fibre and other lighter stuff was blown out.Separating the fibres in the pressed cake to obtain a pure core. |

|

| 10 |

10.Nut and Kernel Recycling section The kernel and the shell are separated by wind filtration and water washing according to the specific gravity of the shell and the kernel. After the separated kernels are dried, the water is reduced to about 6-8% for storage. The separated palm shell is transported to the boiler as fuel.The kernels in the core are recovered and stored. |

|

| 11 |

11.Steam Boilers 1. Has a strong output, high thermal efficiency, stable and reliable operation, overload capacity, fuel, wide applicability, environmental protection and many other advantages. 2. It Provides power and thermal sources for the production process. |

|

| 12 |

12.Power House 1.The use of diesel powered generators and turbine generators, more environmentally friendly energy production and electricity consumption to power. |

|

| 13 |

13.Raw water treatment system After settling, filtration, dosing and other processes to ensure that the water quality, but also to ensure oil quality. 1. Storage and settlement treatment of factory water 2. Filtration of factory water |

|

| 14 |

14.Boiler water treatment system 1. Select the water treatment system according to the water quality, generally divided into softening system and permeation reverse osmosis (RO system) 2. Remove Mg ion and K ion in water, adjust PH value of water, improve steam quality, extend boiler life |

|

| 15 |

15. Effluent Treatment |

|

| 16 |

16.Factory power control system 1.Diesel generators and steam turbine generators need to be switched. Each section is operated as a unit, which makes it easier to operate the entire plant and ensures the coordination of the entire plant. The key equipment adopts PLC control to ensure the operating efficiency of the equipment. |

|